Service

Clean HVAC (Critical Areas)

Design–build HVAC for OTs, ICUs, CSSD, clean rooms & labs—air changes, pressure cascades, filtration and balancing engineered for validated performance.

Balanced flows

ACH, RH & temp per space class

HEPA terminals

Validated filtration strategy

Pressure control

Monitored cascades & alarms

Docs & T&B&V

Audit-ready handovers

Scope

- Heat load & ACH calculations

- Ducting, diffusers & layouts

- AHU/FCU sizing & selection

- Filtration stages (pre/ fine/HEPA)

- Pressure zoning & monitoring

- Cleanroom ceilings/laminar modules

- Insulation, acoustic control

- Controls & BMS integration

- Testing, balancing & validation

- As-builts, O&M & SOPs

Deliverables

- Design calcs, drawings & BOQs

- T&B&V reports & certificates

- Parameter logs & setpoints

- O&M manuals & training

Benefits

- Reliable air quality by design

- Lower rework via upfront clarity

- Traceable validation trail

- Efficient, maintainable systems

Engineered for performance

From laminar zones to noise control, we sweat the details.

Laminar Flow Layouts

Uniform velocity fields, correct throw & coverage.

Low Leakage Enclosures

Duct class & sealing that protect pressure gradients.

Quiet by Design

Fan curves, silencers & layouts tuned for comfort.

Technical specifications

- MERV/HEPA terminal filters sized for duty

- Pre/fine stages for life & efficiency

- Sampling points & PAO testing capability

- Room differential sensors with displays

- Alarm thresholds & logging

- BMS/HMI integration (optional)

- SMACNA/IS standards for fabrication

- Low leakage classification

- Cleanable, accessible terminals

How we deliver

Time-bound delivery with validation baked in.

1

Design

Loads, layouts & BOQs.

2

Procure

Compliant equipment.

3

Execute

QA, safety & supervision.

4

T&B&V

Testing & reports.

5

Docs

As-builts & SOPs.

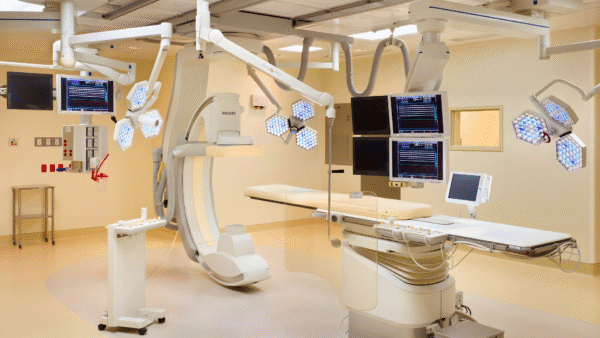

Clean HVAC — placeholder visual.

Gallery

Upgrading or designing clean HVAC?

We’ll map ACH, pressure cascades & validation with clarity.