Service

Clean Rooms (Pharma/GMP)

Turnkey classified suites—architecture, clean HVAC, interlocks & utilities engineered for ISO 5–8 and GMP compliance with full qualification support.

ISO classes

ISO 5–8 / EU-GMP

Modular panels

Flush doors, pass-boxes

Pressure cascades

Monitored & alarmed

Docs & PQ

DQ/IQ/OQ/PQ support

Scope

- User requirements & zoning maps

- Modular panels, covings & flush detailing

- Doors, view panels, interlocks & pass-boxes

- Clean HVAC with terminal HEPA / laminar modules

- Pressure cascade design & monitoring

- Flooring (ESD/vinyl/epoxy) & utilities (PW, drains)

- Electrical, lighting & controls

- Qualification: DQ, IQ, OQ, PQ with records

Deliverables

- Design package, BOQs & interlock diagrams

- As-built drawings & labeling

- Qualification protocols & reports

- O&M manuals, SOPs & training logs

Benefits

- Audit-ready, compliant facilities

- Robust particle & pressure control

- Cleanable, maintainable finishes

- Clear documentation trail

Built clean, validated clean

Corners, seams and flows that pass scrutiny.

Flush Detailing

Minimal ledges, continuous coving, sealed penetrations.

Controlled Interlocks

Airlocks & door logic protecting pressure cascades.

Qualification Support

From DQ to PQ with protocols, deviations & reports.

Technical specifications

- Powder-coated / SS modular panels with flush view panels

- Radius covings, chemical-resistant sealants

- Pass-boxes (dynamic/static) with interlock logic

- Air change targets by class; terminal HEPA & laminar modules

- Room differential monitoring & alarms

- Sampling points & PAO testing capability

- DQ/IQ/OQ/PQ protocols & reports

- Corrective actions & traceability

- O&M manuals, SOPs & training records

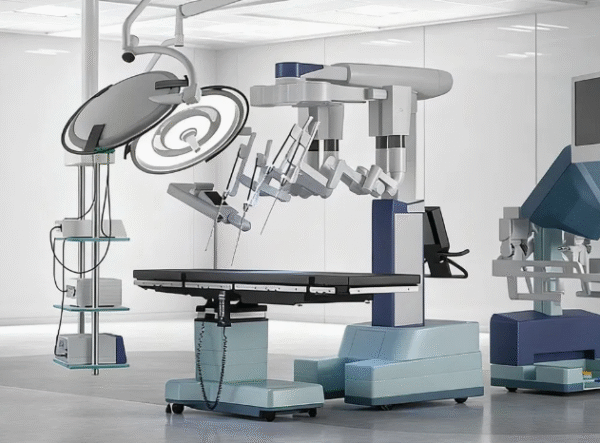

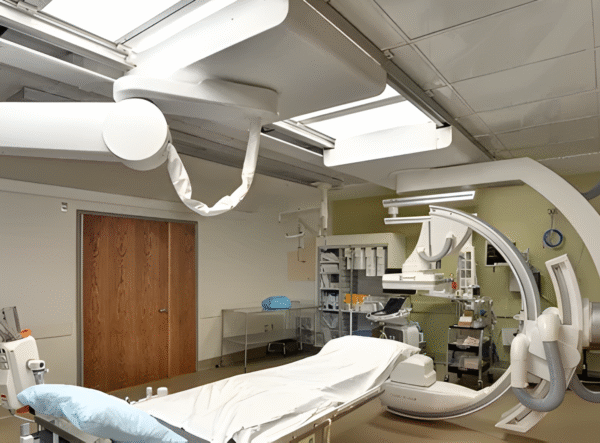

Gallery

Planning a cleanroom suite?

We’ll design the cascade and validate rigorously for your process.