Service

CSSD (Central Sterile Services)

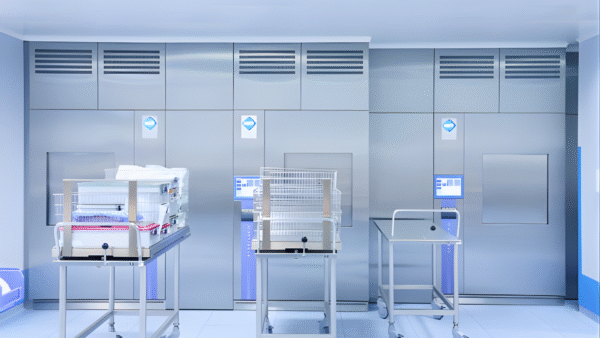

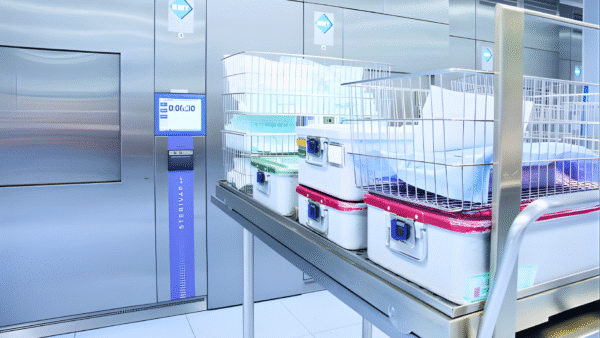

Workflow-first design: decontamination → assembly/packing → sterilization → sterile store—equipment, utilities and documentation aligned for compliance.

Zoned flows

Dirty → clean → sterile

Sterilizers

Steam/Plasma integration

Env. controls

Temp/RH & airflow

Docs

SOPs & validation

Scope

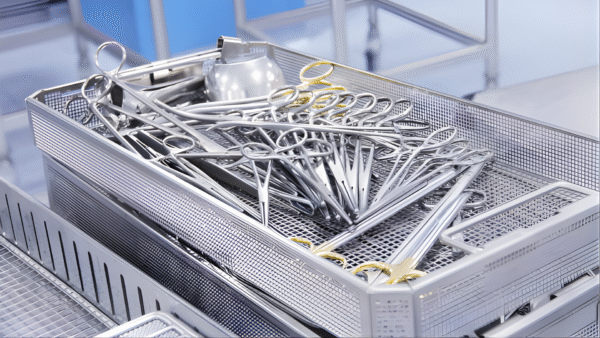

- Process flow mapping & adjacency

- Washers, ultrasonic, dryers

- Packing/inspection benches

- Steam/plasma sterilizers

- Pure steam & pure water (PW)

- Clean HVAC & pressure zoning

- Racks, carts & storage

- Utilities & drains

- Validation protocols

- As-builts, O&M, SOPs

Deliverables

- Layouts, BOQs & utility lists

- Equipment specs & tie-ins

- Validation reports

- SOPs & training

Benefits

- Traceable sterilization cycles

- Clean separation of zones

- Efficient staff movement

- Compliance made simple

Engineered for sterility & throughput

Right utilities, right sequence, right documentation.

One-way Movement

Prevent backflow with smart adjacencies.

Utility Readiness

Steam, PW, drains, power—documented tie-ins.

Validation

Thermal, BI/CI, records & SOPs.

Technical specifications

- Steam/plasma sterilizers with PW/PS connections

- Washers with appropriate drains & filters

- Cycle recorders & maintenance clearances

- Temperature/RH per zone

- Pressure cascades & returns

- HEPA where specified

- Thermal & BI/CI records

- Traceability forms

- SOPs & training logs

CSSD — placeholder visual.

Gallery

Setting up or upgrading CSSD?

We’ll design clean flows and map utilities for reliable cycles.