Medical Gas Pipeline Systems (MGPS)

Design–build MGPS covering networks, manifolds, control panels, zone isolation, alarm systems and terminal units—engineered for safety, traceability and uptime with audit-ready documentation.

Turnkey MGPS

Design → Install → T&C → Docs

Zone safety

Valves, labeling, isolation maps

Alarms & panels

Local/central with logging

Clean interfaces

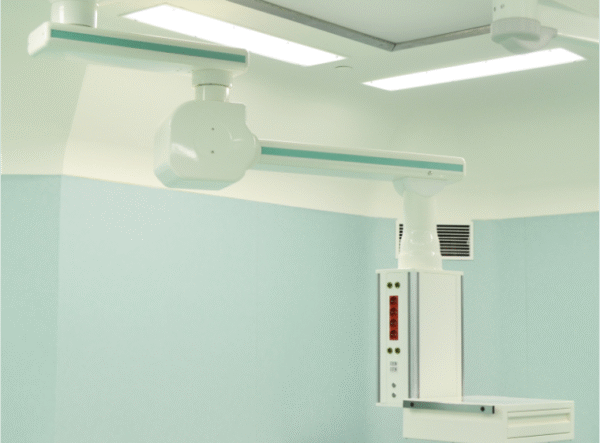

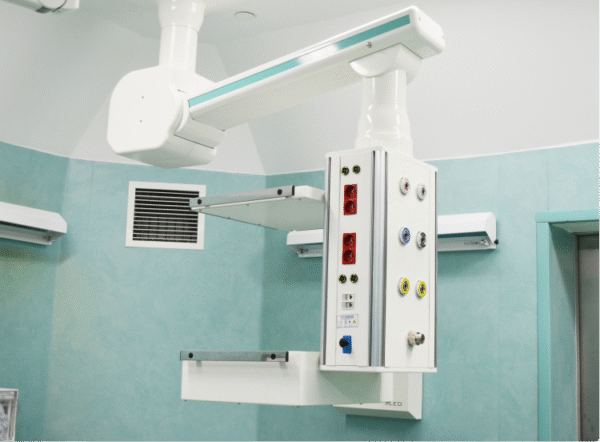

OT/ICU terminals & pendants

Scope

- System design, loads & diversity factors

- P&IDs, routing, sleeves & BOQs

- Manifolds, source plants & banks

- Medical air, vacuum & AGSS sizing

- Copper pipeline with brazing procedures

- Zone valve boxes & isolation strategy

- Area/central alarm panels & sensors

- Terminal units, pendants, bedhead units

- Color coding, labeling & as-built marking

- Testing, purging, degreasing & documentation

Deliverables

- Approved drawings, P&IDs & as-builts

- Pressure/leak test reports, purity certificates

- O&M manuals, SOPs & maintenance plan

- Alarm maps, isolation maps & tags

Benefits

- Safe, traceable distribution with clear isolation

- Minimal downtime through staged commissioning

- Clean interfaces with OTs/ICUs and equipment

- Audit-ready paperwork reduces admin load

What sets our MGPS apart

Reliability, safety and maintainability designed-in.

Clear Isolation Strategy

Zone valve boxes with maps and labeling that speed response.

Source Redundancy

Banked manifolds and duplex/triplex pumps sized for continuity.

Assured Cleanliness

Degreased copper, qualified brazers, oxygen-clean procedures.

Technical specifications

- Degreased medical copper to relevant standards

- Silver brazing (qualified procedure & personnel)

- Clean routing with sleeves and supports

- Medical air, vacuum, AGSS with redundancy

- HP/LP manifolds with changeover

- Quality monitoring for purity & dew point

- Area & central panels with audible/visual alarms

- Pressure, vacuum & flow sensors with logging (optional)

- Integration to BMS/HMI where required

- Pressure, leak, purity & functional tests

- Flushing/purging protocols & cleanliness checks

- As-builts, isolation maps, O&M & SOPs

How we deliver

Time-bound turnkey execution with safety at every stage.

Design

Loads, P&IDs, routes, specs & BOQs.

Procurement

Compliant materials & OEMs.

Execution

Qualified brazers, safety & QA.

T&C

Testing, purging & validation.

Documentation

As-builts, SOPs, isolation maps.

Gallery

Rolling out MGPS or upgrading?

We’ll design for safety and deliver with clean isolation & documentation.